Single Stage Gas Generator

INTRODUCTION OF SINGLE-STAGE GASIFIER TECHNOLOGY

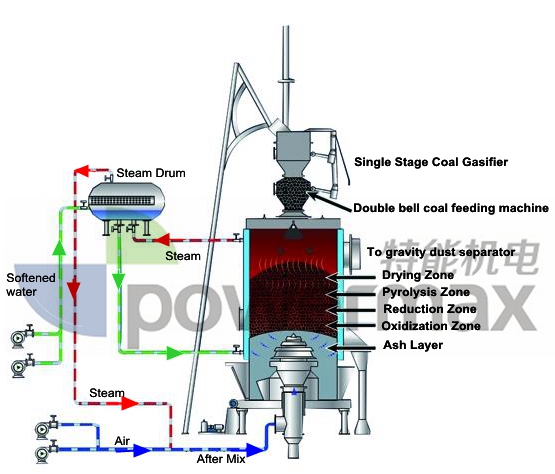

The technology of single-stage gasifier , with 20mm-60mm bituminous coal or anthracite as fuel, is the gasification technology of a series of chemical reactions working inside gasifier., which consists of oxidization, reduction, pyrolysis and drying. Etc. After the technical disposal with optimized alloction of dust-removing , tar-removing and cooling ,etc., the clean coal gas out of gasifier is supplied to industrial kiln by gas pressure adding and transmission system. Hot coal gas and cold coal gas technology are defined according to requirements of different kilns. The whole system includes coal yard, slag yard, coal lifting system, coal bunker, coal feeding system, air supplying system. single-stage gasifier gasifying system. dust-removing and purifying system, light oil catching and recycling system , auto-control system, gas storage, pressure adding and transmission system.

The technology of single-stage gasifier , with 20mm-60mm bituminous coal or anthracite as fuel, is the gasification technology of a series of chemical reactions working inside gasifier., which consists of oxidization, reduction, pyrolysis and drying. Etc. After the technical disposal with optimized alloction of dust-removing , tar-removing and cooling ,etc., the clean coal gas out of gasifier is supplied to industrial kiln by gas pressure adding and transmission system. Hot coal gas and cold coal gas technology are defined according to requirements of different kilns. The whole system includes coal yard, slag yard, coal lifting system, coal bunker, coal feeding system, air supplying system. single-stage gasifier gasifying system. dust-removing and purifying system, light oil catching and recycling system , auto-control system, gas storage, pressure adding and transmission system.

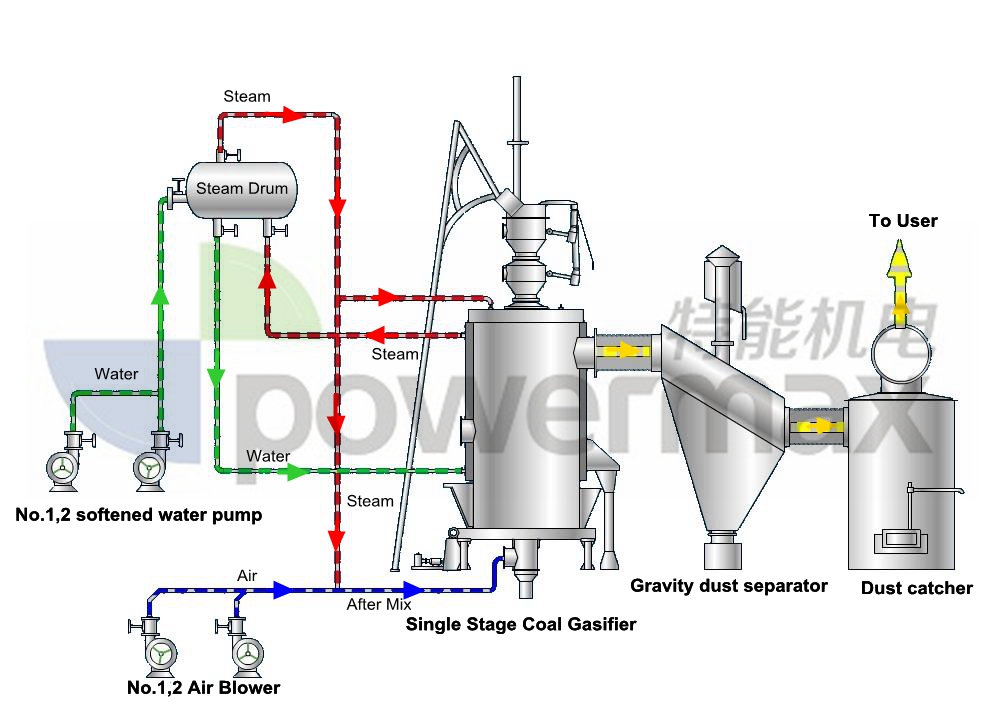

HOT GAS STATlON OF SINGlE STAGE GASIFIER

The single stage gasifier is of continuous gas-making and whole water jacket type. Saturated air, which is formed by self-produced 0.294MPa steam and air from blower, is used as gasification agent and comes into gasifier from the bottom check valve. Block coal is broken up and filtrated to size of 25- 50mm or 50 – 80mm.Then the coal is fed into coal bunker by coal feeding system and be fed into gasifier Gas produced by gasifier is removed dusts by gravitational dust cleaner and cyclone dust catcher and finally be sent to user.

The single stage gasifier is of continuous gas-making and whole water jacket type. Saturated air, which is formed by self-produced 0.294MPa steam and air from blower, is used as gasification agent and comes into gasifier from the bottom check valve. Block coal is broken up and filtrated to size of 25- 50mm or 50 – 80mm.Then the coal is fed into coal bunker by coal feeding system and be fed into gasifier Gas produced by gasifier is removed dusts by gravitational dust cleaner and cyclone dust catcher and finally be sent to user.

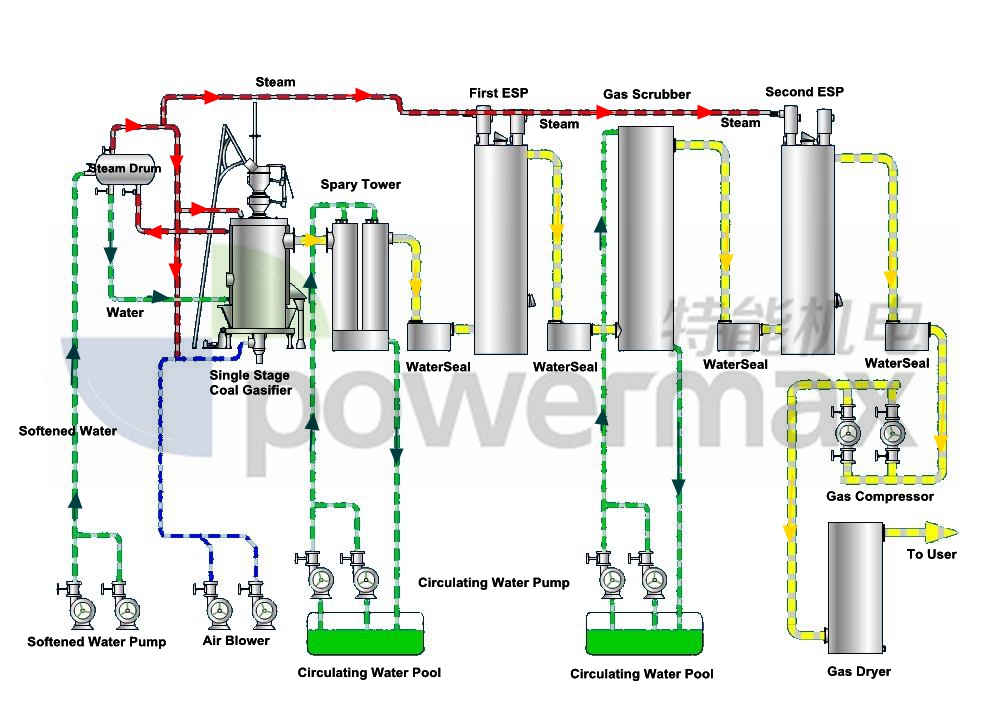

COLD GAS STATION OF SINGLE STAGE GASIFIER(ANTHRACITE)

The technological flow(anthracite):unpurified gas produced by gasifier, which temperature is 400 - 600℃, gets into double-standpipe to be cooled by hot circulating water and washed out part of dust which discharged from the bottom water seal Then the gas gets out from the top of standpipe which temperature is 80 - 90t:, and then gets into the washing tower for cooling and dust removing, the temperature is lowered to 35 - 45t: After removed dust by electrostatic precipitator, the gas is pressurized by gas booster fan, desulfurized by desulfurizeding tower, and removed water by drop catcher, at last be sent to the user.

The technological flow(anthracite):unpurified gas produced by gasifier, which temperature is 400 - 600℃, gets into double-standpipe to be cooled by hot circulating water and washed out part of dust which discharged from the bottom water seal Then the gas gets out from the top of standpipe which temperature is 80 - 90t:, and then gets into the washing tower for cooling and dust removing, the temperature is lowered to 35 - 45t: After removed dust by electrostatic precipitator, the gas is pressurized by gas booster fan, desulfurized by desulfurizeding tower, and removed water by drop catcher, at last be sent to the user.

Feedback form contact with us

Related Product