Two-Stage Gas Generator

INTRODUCTION OF TWO-STAGE GASIFIER TECHNOLOGY

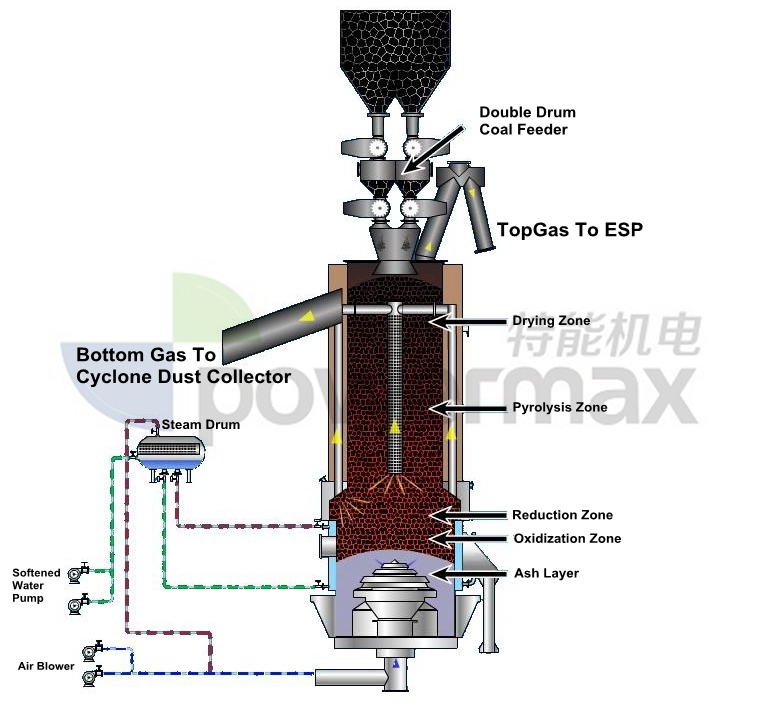

The two- stage coal gasifier is a gasifying equipment including carbonizing stage and gasifying stage, with 40- 60mm bituminous coal for fuel. In the upper stage coal is carbonized. The carbonized coal becomes semi cokes, then gets down to be gasified in lower stage Carbonization and gasification of coal are finished in the same equipment. The carbonizing and gasifying gas, after optimized allocation is disposed by dust- removing, tar-removing, Cooling and sulfur- removing technology. The clean coal gas out of gasifier is supplied to industrial kiln by gas pressure adding and transmission system .According to different requirements on coal gas quality of various kinds of kiln , it is composed of two-stage hot detarring gas and two-stage cold clean gas, two different technologies. The whole system includes coal lifting system, coal lifting system, air supplying system, two-stage gasifier gasifying system, dust-removing and purifying system, light oil catching and recycling system, phenol water disposal and incinerating system, desulphurizing system, auto-control system, gas storage, pressure adding and transmission system

The two- stage coal gasifier is a gasifying equipment including carbonizing stage and gasifying stage, with 40- 60mm bituminous coal for fuel. In the upper stage coal is carbonized. The carbonized coal becomes semi cokes, then gets down to be gasified in lower stage Carbonization and gasification of coal are finished in the same equipment. The carbonizing and gasifying gas, after optimized allocation is disposed by dust- removing, tar-removing, Cooling and sulfur- removing technology. The clean coal gas out of gasifier is supplied to industrial kiln by gas pressure adding and transmission system .According to different requirements on coal gas quality of various kinds of kiln , it is composed of two-stage hot detarring gas and two-stage cold clean gas, two different technologies. The whole system includes coal lifting system, coal lifting system, air supplying system, two-stage gasifier gasifying system, dust-removing and purifying system, light oil catching and recycling system, phenol water disposal and incinerating system, desulphurizing system, auto-control system, gas storage, pressure adding and transmission system

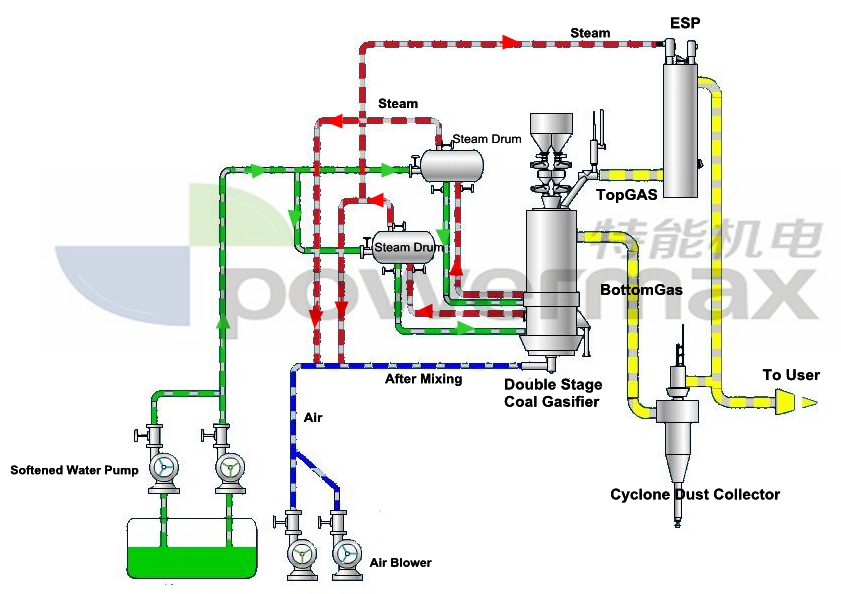

HOT DETARRING GAS STATION OF TWO STAGE GASIFIER

The technological flow: Up-stage gas gets into electrostatic precipitator, which work temperature is between 90 - 150℃, where the tar fog-drops and dusts are polarized and then in fluxed on inside wall of polar tube, and finally flows automatically to tar pool. Firstly, down0stage gas gets into the cyclone dust remover and centrifugally separated. The temperature is lowered to abou1450 - 550℃. Up-stage gas is mixed with down-stage gas and then sent 10 users.

The technological flow: Up-stage gas gets into electrostatic precipitator, which work temperature is between 90 - 150℃, where the tar fog-drops and dusts are polarized and then in fluxed on inside wall of polar tube, and finally flows automatically to tar pool. Firstly, down0stage gas gets into the cyclone dust remover and centrifugally separated. The temperature is lowered to abou1450 - 550℃. Up-stage gas is mixed with down-stage gas and then sent 10 users.

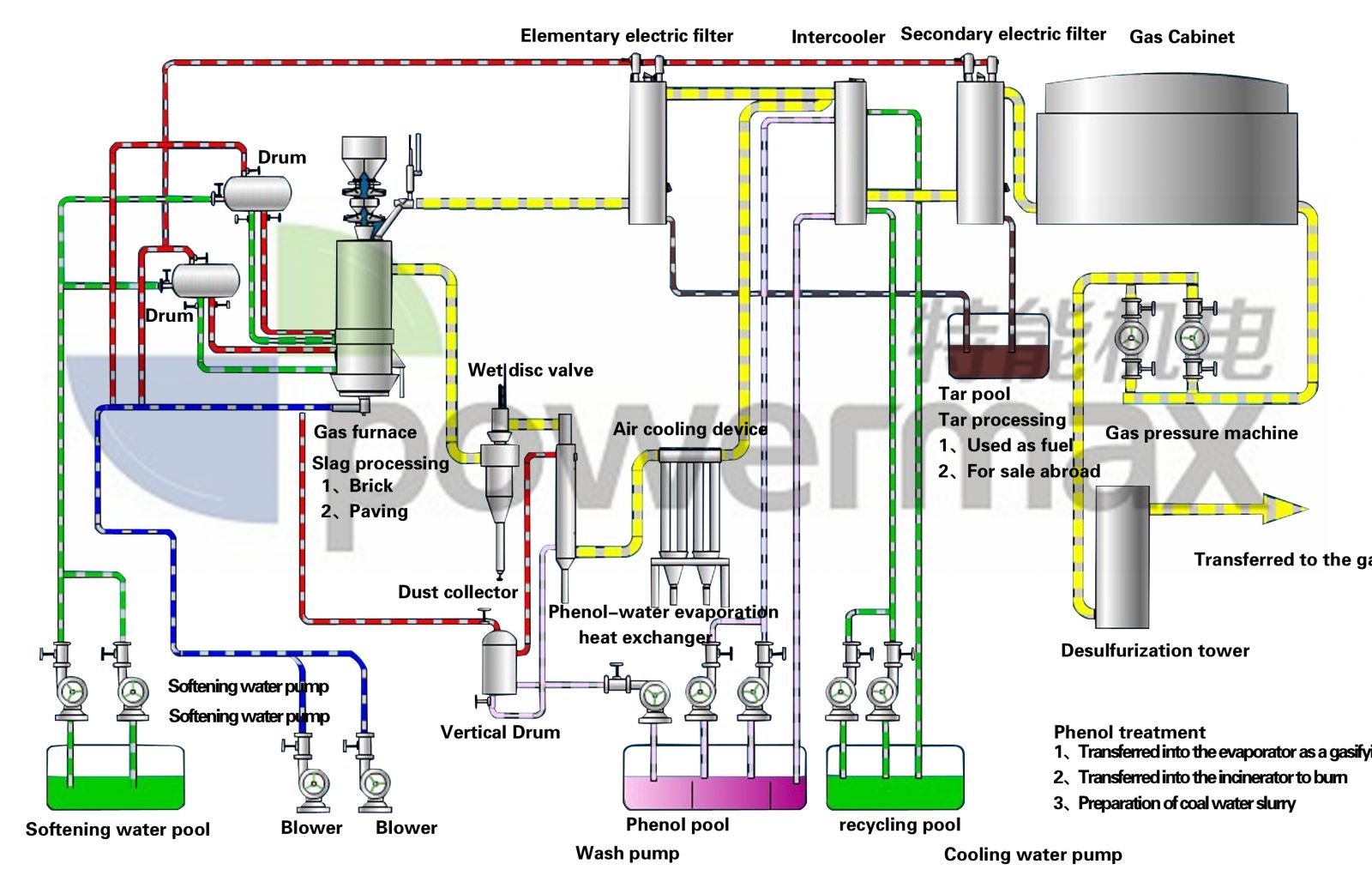

COLD GAS STATION OF TWO STAGE GASIFIER

Decontaminating and cooling process of up-stage gas: Up-stage gas firstly gets into electrostatic precipitator, which work temperature is about 90 - 150℃. In this part,heavy tar and dust are separated. Up-stage gas then gels into indirect cooler, in where the gas is cooled to 35 - 45℃. Firstly, dust is centrifugally separated from down-stage gas and the temperature is lowered to about 450 - 550℃, secondly, the gas comes into exhausted heat exchanger to recover the gas sensible heat with the temperature dropping to about 180- 220℃; thirdly, the gas temperature is dropped to 65 - 80℃ in wind cooler; and finally, its temperature is lowered to 35 - 45℃ by circulating cooling water in indirect cooler. Then the up-stage gas mixed with down-stage gas gets into electrostatic precipitator II to remove oil and dust again. The gas is pressurized by gas booster fan, desulfurized by desulfurizing tower, and then sent to the user.

Decontaminating and cooling process of up-stage gas: Up-stage gas firstly gets into electrostatic precipitator, which work temperature is about 90 - 150℃. In this part,heavy tar and dust are separated. Up-stage gas then gels into indirect cooler, in where the gas is cooled to 35 - 45℃. Firstly, dust is centrifugally separated from down-stage gas and the temperature is lowered to about 450 - 550℃, secondly, the gas comes into exhausted heat exchanger to recover the gas sensible heat with the temperature dropping to about 180- 220℃; thirdly, the gas temperature is dropped to 65 - 80℃ in wind cooler; and finally, its temperature is lowered to 35 - 45℃ by circulating cooling water in indirect cooler. Then the up-stage gas mixed with down-stage gas gets into electrostatic precipitator II to remove oil and dust again. The gas is pressurized by gas booster fan, desulfurized by desulfurizing tower, and then sent to the user.

Feedback form contact with us

Related Product