iomass Gasification Coupled Efficient Power Generation And Poly-Generation Technology

Mainly Three Kinds Of Biomass Coupling Power Generation Technologies At Present:

Biomass is mixed with coal and then put into boiler for comnustion.This method has higher requirements for fuel treatment and combustion equipment,and has the problem of low temperature alkali metal corrosion.So the boiler bumer needs to be remoulded.

The biomass burning boiler generates steam directly,and this part of steam can be fed into the reheater if pulverized coal fumace or into the low-pressure cylinder of steam turbine coupling method.This coupling mode.due to the existence of relatively independent biomass boiler system,has no influence on the combustion of coal-fired boilers.However,the system is complex,so the investment cost is little higher.

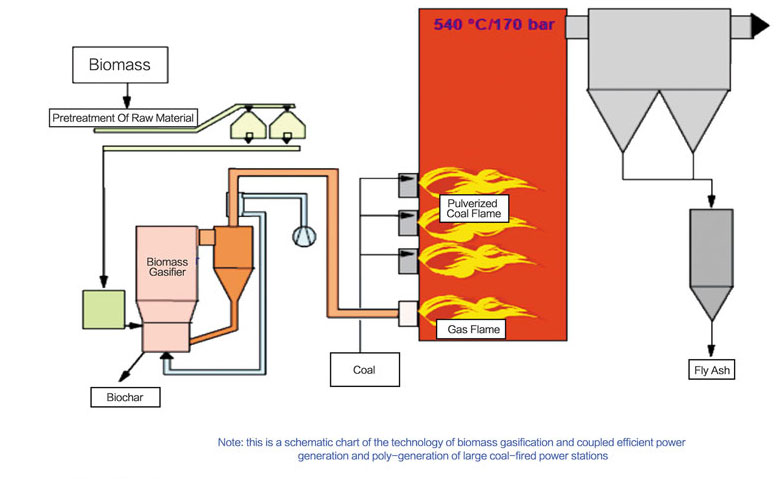

Biomass gasification produces gas, mixed with coal to combustion.This technology is the main application technology. The first two types of biomass coupling power generation technologies are types of biomass direct combustion,and the biomass gasification coupled efficient power generation and polygeneration technologies provided by Powermax are biomass gasification technologies.

Technical Principle

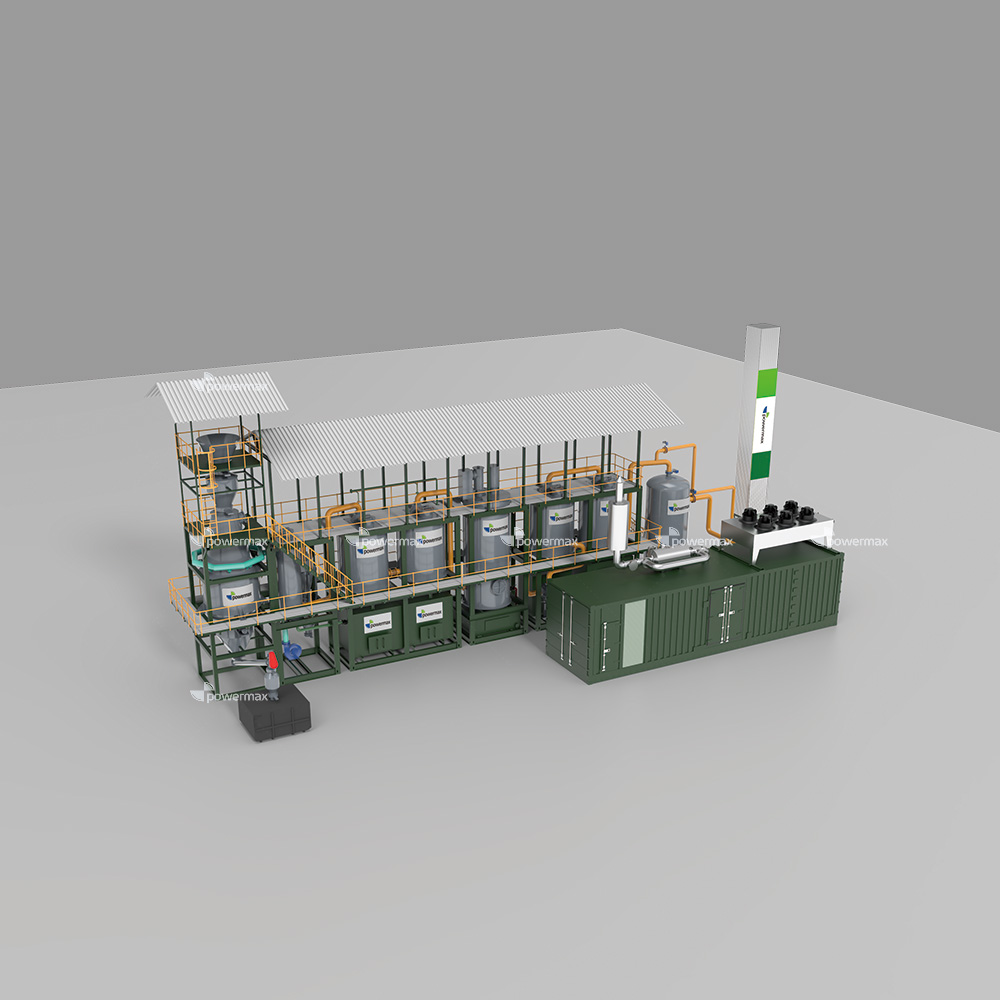

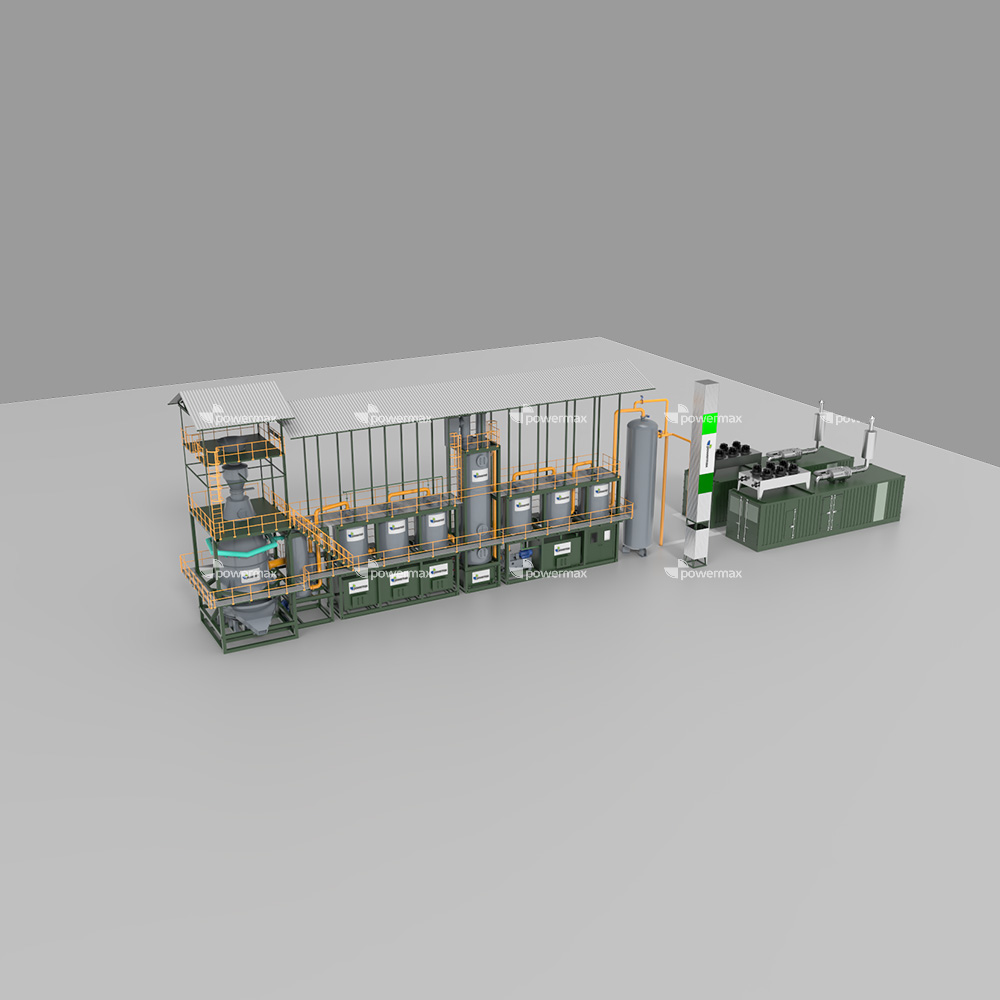

Process Flow Chart

Environmental benefits:Due to biomass gas replacement of coal,it reduces CO2/SO2 emissions,while combustion of low calorific value gas in boilers reduces NOX emissions.

Economy:After the biomass gas is added into the boiler system,the efficient combustion of gas forms a high temperature zone,which is conducive to the complete combustion of coal powder.While the coal power system remains efficient ,the efficiency of biomass conversion into electric energy can reach 37%,higher than the existing biomass direct combustion power generation(22-30%).The biochar obtained from gasification can be used as high quality energy,soil conditioner,reducing agent,fertilizer slow-release carrier and carbon dioxide sequestration agent,which have higher economic benefits.

Flexibility:This technical route is suitable for coal-fired power fenerationg units of different capacities.Biomass gasification and reburning to generate power make full use of the original high-efficiency power generation equipment of the power station to ensure higher power generation efficiency in any scale.National policy:Biomass gasification power generation can monitored by gas flow rate,temperature and gas composition parameters to calculate inde

Pendently and electricity and power grid enterprises shall settle separately.At present the way has been officially confirmed by the national development and reform commission(Implementation of Biomass Power Generation Coal Coupling of the Pilot),and it can be offered eith biomass electricity price subsidies.