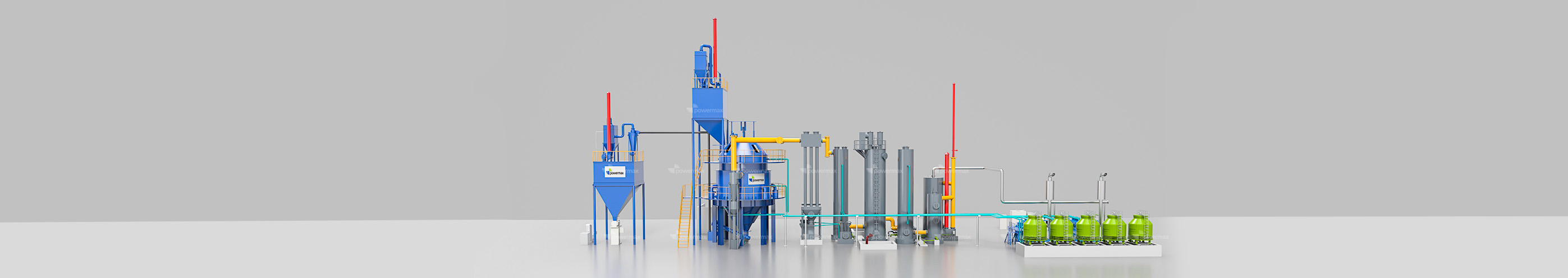

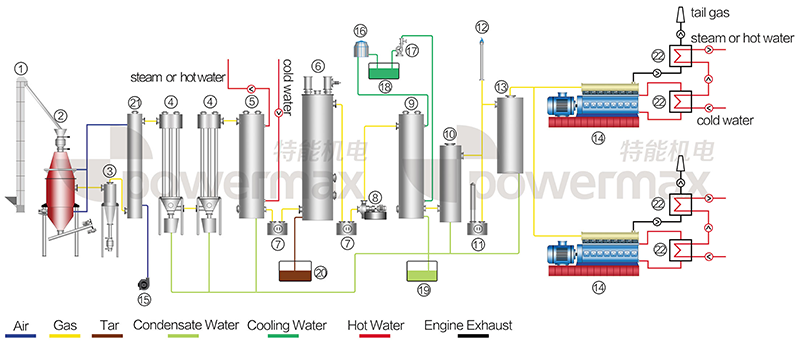

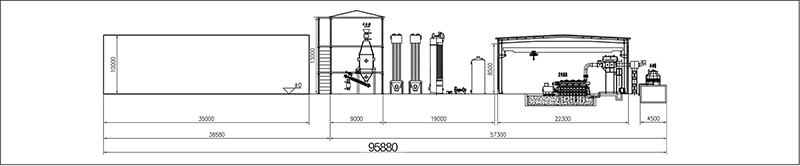

- 1. Elevator

- 2. Gasifier

- 3. Cyclone

- 4. Air cooler

- 5. Indirect cooler

- 6. Electric tar precipitator

- 7. Isolation seal

- 8. Roots blower

- 9. Indirect cooler

- 10.Water drop catcher

- 11. Water bleeding

- 12. Gas flare

- 13. Buffer tank

- 14. Generator set

- 15. Air blower

- 16. Cooling tower

- 17. Water pump

- 18. Cooling water pool

- 19. Condensate water pool

- 20. Tar tank

- 21. Hot air heat exchanger

- 22. Heat recovery boiler

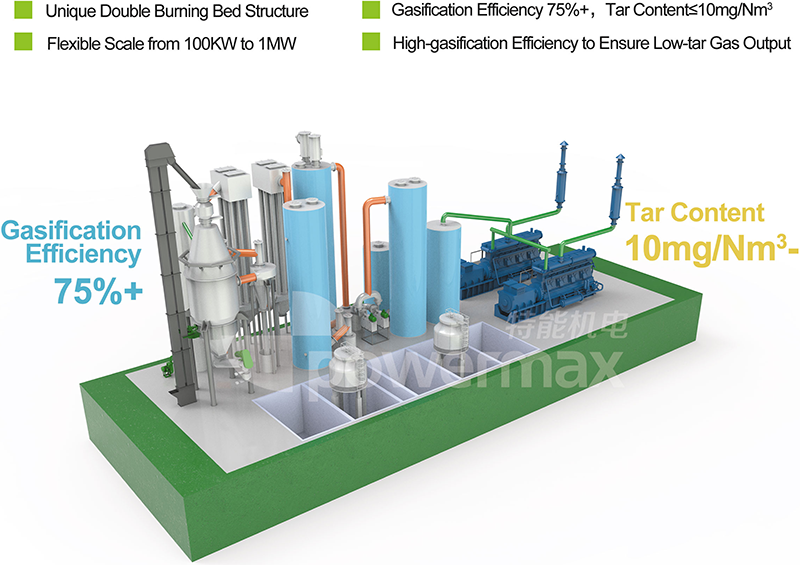

Powermax's Feature - TFBG System

Twin Fire Fixed Bed Gasifier

TFBG Introduction

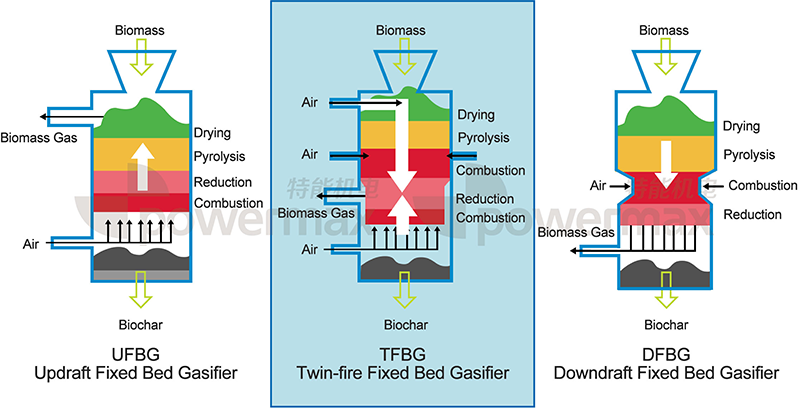

POWERMAX Twin-Fire Fixed Bed Gasifier (TFBG), developed and researched independently by POWERMAX, is a high-efficient biomass fixed bed gasifier that combines the advantages of traditional Updraft Fixed Bed Gasifier (UFBG) and Downdraft Fixed Bed Gasifier (DFBG) and improves the disadvantages of the two gasifiers.

| COMPARISON | ADVANTAGES | DISADVANTAGES |

| Traditional Updraft Fixed Bed Gasifier(UFBG) | High thermal efficiency | Dirty gas with much tar |

| Traditional Downdraft Fixed Bed Gasifier(DFBG) | Low thermal efficiency Clean gas with little tar | Low thermal efficiency |

| Powermax Efficient Twin-Fire Fixed Bed Gasifier(TFBG) | High thermal efficiency clean gas with little tar |

Suitable Fuel:

Briquettes fuels like wood chip, rice husk block, straw block, coal, etc.

-

wood chip

-

rice husk block

-

straw block

-

coal

Technical Parameters of TFBG Power Plant

| Model | 50TFBG | 100TFBG | 200TFBG | 300TFBG | 400TFBG | 500TFBG | 600TFBG | 800TFBG | 1000TFBG | 1200TFBG | 1500TFBG | 2000TFBG |

| Rated Power(kw) | 50 | 100 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1200 | 1500 | 2000 |

| Rated Frequency | 50 /60 HZ | |||||||||||

| Rated Voltage(V) | 220 / 400 / 440 / 6300 / 6600 / 11000 /13800 | |||||||||||

| Model of Gasifier | TFBG50 | TFBG100 | TFBG200 | TFBG300 | TFBG400 | TFBG500 | TFBG600 | TFBG800 | TFBG1000 | TFBG1200 | TFBG1500 | TFBG2000 |

| Gasifier Type | Twin-Fire Fixed Bed Gasifier | |||||||||||

| Biomass Moisture Requirement | ≤20~35%(wet basis) | |||||||||||

| Biomass Size Requirment | Diameter 10mm-80mm;Length 10-80mm; | |||||||||||

| Biomass Consumption(Kg/hr) | 50-100 | 100-200 | 200-400 | 300-600 | 400-800 | 500-1000 | 600-1200 | 800-1600 | 1000-2000 | 1200-2400 | 1500-3000 | 2000-4000 |

| Gas Production(Nm3/h) | 125-150 | 250-300 | 500-600 | 750-900 | 1000-1200 | 1250-1500 | 1500-1800 | 2000-2400 | 2500-3000 | 3000-3600 | 3750-4500 | 5000-6000 |

| Ash Discharge Type | Wet Ash Type/ Dry Ash Type | |||||||||||

| Type of Gas Purification | Dry Type Gas Purification System | |||||||||||

| Heat Value of Gas | ≥1200Kcal/Nm3 | |||||||||||

| Gas Composition | CO-15~20%, CO2-8~12%, CH4-upto 3% H2-15~20% N2-45~50% | |||||||||||

| Model of Gensent | 50GFLS | 100GFLS | 100GFLS | 300GFLS | 400GFLS | 500GFLS | 300GFLS | 400GFLS | 1000GFLS | 400GFLS | 500GFLS | 1000GFLS |

| Qty of Genset | 1 | 1 | 2 | 1 | 1 | 1 | 2 | 2 | 1 | 3 | 3 |

2 |

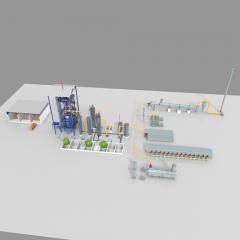

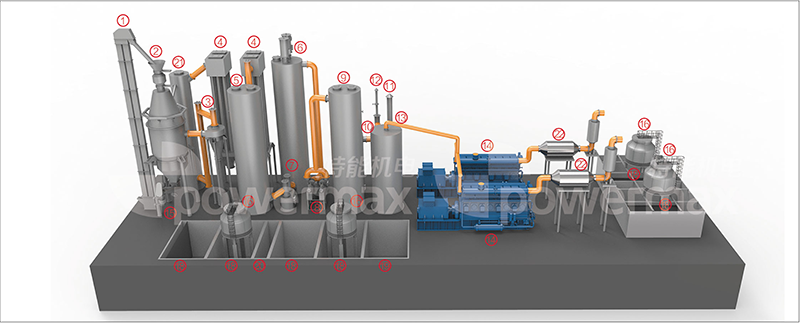

Layout of Twin-Fire fixed bed gasification power generation system

3D Layout of 1MW Twin-Fire Fixed Bed Gasification Power Generation System

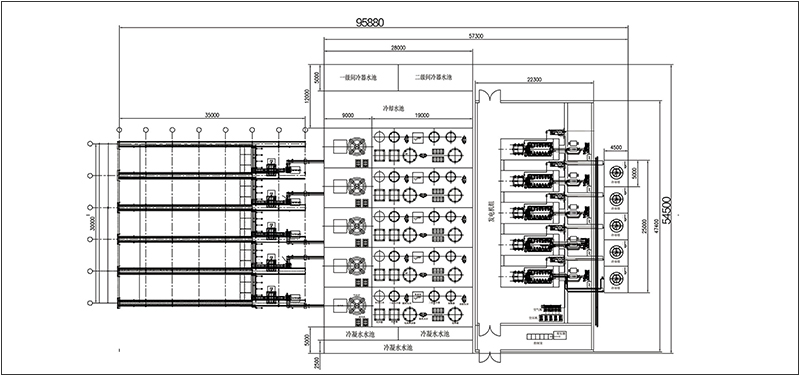

Floor Plan of 5MW Twin-Fire Fixed Bed Gasification Power Generation System

(only for reference; take the engineering diagram as criterion)

Elevation of 5MW Twin-Fire Fixed Bed Gasification Power Generation System

(only for reference; take the engineering diagram as criterion)

Benefit analysis

The biomass gasification polygeneration technology can efficiently transforms the biomass into electric energy or thermal energy and simultaneously produce the biomass charcoal and the biomass wood vinegar. The electricity generated can be directly connected to the grid with a price subsidy of 0.75 yuan/KWH; Biochar can be used in production, barbecue charcoal and carbon base fertilizer and other products; The biomass extract obtained by purification of wood vinegar is widely used in pharmaceutical and food industries or as leaf fertilizer.

Take 5MW Biomass Wood Pyrolysis Gasification Co-generation of Electricity, Carbon, Liquid and Thermal System As An Example for Benefit Analysis

The biomass gasification polygeneration technology can efficiently transforms the biomass into electric energy or thermal energy and simultaneously produce the biomass charcoal and the biomass wood vinegar. The electricity generated can be directly connected to the grid with a price subsidy of 0.75 yuan/KWH; Biochar can be used in production, barbecue charcoal and carbon base fertilizer and other products; The biomass extract obtained by purification of wood vinegar is widely used in pharmaceutical and food industries or as leaf fertilizer.

Take 5MW Biomass Wood Pyrolysis Gasification Co-generation of Electricity, Carbon, Liquid and Thermal System As An Example for Benefit Analysis

| Project Name | Unit | Value | Comment |

| Consumption&Output | |||

| Biomass Consumption | kg/h | 5,000 | |

| Generated Energy | kw | 5,000 | The long running load is 90% |

| Biochar Yield | kg/h | 250 | |

| Biomass Extract Yield | kg/h | 500 | |

| Steam Output | t/h | 5 | Waste heat utilization of generator sets |

| Hot Water Output | t/h | 50 | Transfer utilization of cylinder water and gas heat |

| Benefit Analysis | |||

| Total Project Investment | USD | 11,705,147.11 | Differences due to different price of distinct area |

| Annual Running-time | h | 7,500 | |

| Self-consuming Electricity | % | 10 | |

| Fuel Cost | USD | 1,646,036.31 | 43.89 USD/t |

| Staff Salary | USD | 263,365.81 | |

| Maintenance and Repair Costs | USD | 117,051.47 | |

| Oil Consumption | USD | 93,641.18 | 1kwh consuming 1g engine oil |

| Equipment Amortization | USD | 365,785.85 | |

| Management Cost | USD | 43,894.30 | |

| Annual Total Cost | USD | 2,529,774.92 | |

| Annual Line Capacity | kwh | 33,750,000 | Self-consumption electricity |

| Annual Electricity Income | USD | 3,703,215.92 | 0.11 USD/kwh |

| Annual Biochar Income | USD | 411,143.29 | Charcoal 219.47 USD/t |

| Annual Biomass Extract Income | USD | 219,471.51 | 58.53 USD/t |

| Annual Steam Income | USD | 1,097,357.54 | 29.26 USD/t |

| Annual Hot Water Income | USD | 1,097,357.54 | 2.93 USD/t |

| Gross Annual Income | USD | 6,528,545.80 | |

| Annual Profit | USD | 3,998,770.88 | |

| Investment Payoff Period | year | 3.4 | Half a year construction period included |

-

Biochar

-

Carbon Basal Fertilizer

-

Leaf Fertilizer

-

Insect Repellent

Powermax Project Presentation

South Africa Durban 1MW biomass gasification power generation station(scrap pallet wood)

Thailand Rayong 100kw biomass gasification power generation station(wood wastes-RDF )

Greece 1MW biomass gasification power generation station(wood chips)

Feedback form contact with us