Powermax Syngas Generator Set

POWERMAX 300 SERIES GENERATOR SETS

FOR GAS WITH LOW CALORIFIC VALUE

Applicable to combustible gas with calorific value over 800Kcal/Nm3

like biomass gas, straw gas, coal gas, syngas, pyrolysis gas, biogas, etc. (400-1000KW)

POWERMAX 300 SERIES GAS GENERATOR SETS

Introduction

The 300 series gas generator sets are widely used in clean energy power generation and comprehensive utilization of waste

heat,such as syngas,straw gas, coal gas, natural gas, biogas, blast furnace gas, coke oven gas, blue carbon gas, etc. The

rotate speedis mainly at 500r/min and 600r/min,and the power ranges from 400kW to 3000kW.

The 300 series gas generator sets use various combustible gas as raw materials for combustion to drive the engine to generate

electricity. The engines based on Xichai 300 diesel engine, combined with the advantages of the large cylinder bore and long

stroke of 300 diesel engine. The generator sets have ave fully learned from the advanced gas engine technology both at home

and aboard. Targeted improvement and R&D have been conducted to meet the requirements of all kinds of combustible gas to

ensure the combustion function and reliability of gas engine. In this case, the generator sets can run more smoothly and run

for a longer period under full load. Moreover, the interconnection can be more convenient, and the comprehensive efficiency of

co-generation can be realized by utilizing waste heat. 300 series gas generator sets can output at high, medium, and low

voltage, achieve automatic parallel and grid connected, and have become the most popular exported products among the

same power.

Main Technical Features

In practical application, 300 series gas generator sets which is at medium rotate speed, compared with other equipment in

China, has obvious advantages:

1. Able to output at high, medium, and low voltage, and reduce initial investment and operating cost

300 series gas generating sets can be customized with output of high, medium and low voltage at 10500V, 6300V and 400V to

meet various needs of users. Moreover, the initial investment does not have to include transformers, which can reduce copper

losses, contributing to the reduction of operating costs. It not only can be combined to the grids, but can run directly with load,

which greatly improves its economic benefit.

2.The stability of output power ensured by the large bore and long stroke

The prime mover of 300 series gas generator sets is remould from 300 series diesel engine with a diameter of 300mm with the

characteristics of large cylinder diameter, long stroke, low rotate speed, and large power reserve. It is more suitable for the gas

with low pressure than generator sets at high rotate speed, and it is the best prime mover for gas generator sets with stable

output power.

3.Long service life ensured by the low rotate speed

The rotate speed is 500r/min and 600r/min. Low rotate speed can reduce the wear of friction pairs of engine parts, increase the

service life of the parts,reduce the reserve of spare parts, and improve the economic benefits of users.

4.The normally aspirated non-pressurized generator sets applicable to various gas with low failure rate

The single cylinder of 300 series generator sets has large emissions, with which low-pressure gas and air can be normally

aspirated into the prime mover (the pressure of air source should be over than 2kPa), so that the generator sets can be

applied to more kinds of gas, and the transmission of low-pressure gas is safer. Moreover, With self-aspirating air intake, mixed

gas can enter the combustor directly without air-intake parts like turbocharger and intercooler, so that the failure rate can be reduced.

5.A concise structure and convenient maintenance with simplified layout of straight forward structure of generator sets

300 series gas engine is straight forward engine with large operation space for maintenance, especially the crankshaft upright

structure which greatly saves the maintenance time and costs, and can be fixed on site no matter set overhaul or shafting

maintenance.

6.Security and high-efficiency of gas ensured by several lines of defense

The advanced air-fuel ratio control technology ensures that the engine is proportional to the ideal mixture. The engine intake

pipe is equipped with an explosion-proof valve. Once the temper is automatically released, the flame arrester installed on the

pipe quenches the flame to prevent the flame from spreading. The solenoid valve will quickly cut off the gas source to ensure

the safety of the genset.

7.Recycling of waste heat and realizing comprehensive utilization of gas-fired cogeneration

The exhaust gas of the genset is directly used in the waste heat boiler to generate hot water or steam. The genset can be cooled

by circulating hot water to provide heating bath and other heat. Through comprehensive utilization, the comprehensive heat

efficiency of the gas can reach 70%, which improves economic benefits.

8.Online detection and automatic control can be realized by computer monitoring management system

Operation data can be monitored online with monitoring system, and remote management can be realized with functions like

automatic grid connect, fault diagnosis, automatic adjustment of air-fuel ratio, etc.

Introduction

The 300 series gas generator sets are widely used in clean energy power generation and comprehensive utilization of waste

heat,such as syngas,straw gas, coal gas, natural gas, biogas, blast furnace gas, coke oven gas, blue carbon gas, etc. The

rotate speedis mainly at 500r/min and 600r/min,and the power ranges from 400kW to 3000kW.

The 300 series gas generator sets use various combustible gas as raw materials for combustion to drive the engine to generate

electricity. The engines based on Xichai 300 diesel engine, combined with the advantages of the large cylinder bore and long

stroke of 300 diesel engine. The generator sets have ave fully learned from the advanced gas engine technology both at home

and aboard. Targeted improvement and R&D have been conducted to meet the requirements of all kinds of combustible gas to

ensure the combustion function and reliability of gas engine. In this case, the generator sets can run more smoothly and run

for a longer period under full load. Moreover, the interconnection can be more convenient, and the comprehensive efficiency of

co-generation can be realized by utilizing waste heat. 300 series gas generator sets can output at high, medium, and low

voltage, achieve automatic parallel and grid connected, and have become the most popular exported products among the

same power.

Main Technical Features

In practical application, 300 series gas generator sets which is at medium rotate speed, compared with other equipment in

China, has obvious advantages:

1. Able to output at high, medium, and low voltage, and reduce initial investment and operating cost

300 series gas generating sets can be customized with output of high, medium and low voltage at 10500V, 6300V and 400V to

meet various needs of users. Moreover, the initial investment does not have to include transformers, which can reduce copper

losses, contributing to the reduction of operating costs. It not only can be combined to the grids, but can run directly with load,

which greatly improves its economic benefit.

2.The stability of output power ensured by the large bore and long stroke

The prime mover of 300 series gas generator sets is remould from 300 series diesel engine with a diameter of 300mm with the

characteristics of large cylinder diameter, long stroke, low rotate speed, and large power reserve. It is more suitable for the gas

with low pressure than generator sets at high rotate speed, and it is the best prime mover for gas generator sets with stable

output power.

3.Long service life ensured by the low rotate speed

The rotate speed is 500r/min and 600r/min. Low rotate speed can reduce the wear of friction pairs of engine parts, increase the

service life of the parts,reduce the reserve of spare parts, and improve the economic benefits of users.

4.The normally aspirated non-pressurized generator sets applicable to various gas with low failure rate

The single cylinder of 300 series generator sets has large emissions, with which low-pressure gas and air can be normally

aspirated into the prime mover (the pressure of air source should be over than 2kPa), so that the generator sets can be

applied to more kinds of gas, and the transmission of low-pressure gas is safer. Moreover, With self-aspirating air intake, mixed

gas can enter the combustor directly without air-intake parts like turbocharger and intercooler, so that the failure rate can be reduced.

5.A concise structure and convenient maintenance with simplified layout of straight forward structure of generator sets

300 series gas engine is straight forward engine with large operation space for maintenance, especially the crankshaft upright

structure which greatly saves the maintenance time and costs, and can be fixed on site no matter set overhaul or shafting

maintenance.

6.Security and high-efficiency of gas ensured by several lines of defense

The advanced air-fuel ratio control technology ensures that the engine is proportional to the ideal mixture. The engine intake

pipe is equipped with an explosion-proof valve. Once the temper is automatically released, the flame arrester installed on the

pipe quenches the flame to prevent the flame from spreading. The solenoid valve will quickly cut off the gas source to ensure

the safety of the genset.

7.Recycling of waste heat and realizing comprehensive utilization of gas-fired cogeneration

The exhaust gas of the genset is directly used in the waste heat boiler to generate hot water or steam. The genset can be cooled

by circulating hot water to provide heating bath and other heat. Through comprehensive utilization, the comprehensive heat

efficiency of the gas can reach 70%, which improves economic benefits.

8.Online detection and automatic control can be realized by computer monitoring management system

Operation data can be monitored online with monitoring system, and remote management can be realized with functions like

automatic grid connect, fault diagnosis, automatic adjustment of air-fuel ratio, etc.

-

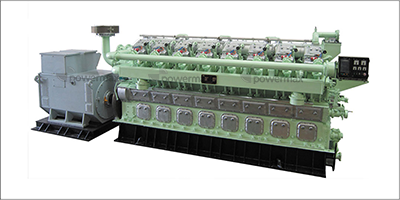

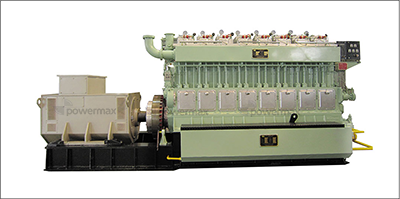

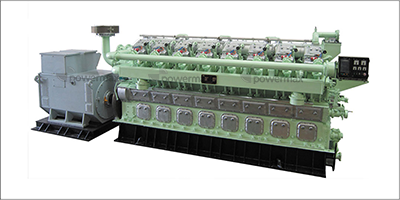

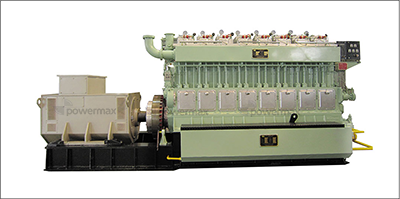

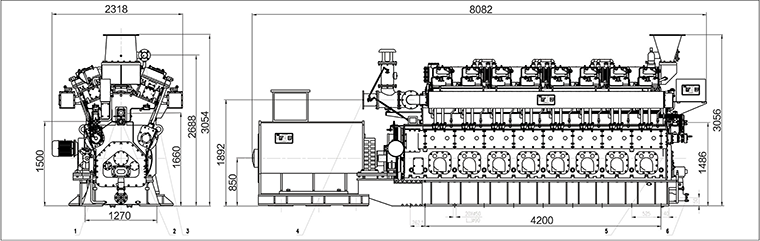

800-1000KW Gas Generator Sets with Low Caloric Value (16V300)

-

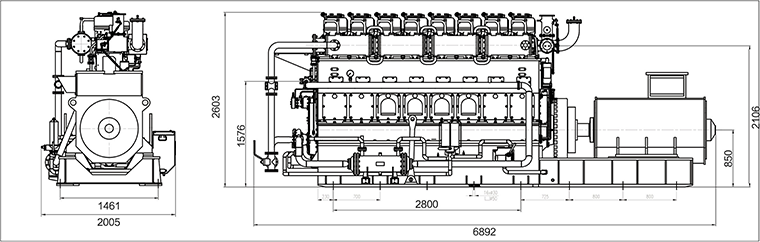

400-500KW Gas Generator Sets with Low Caloric Value (8300)

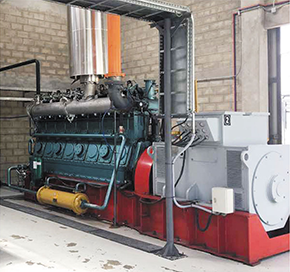

POWERMAX 300 Series Syngas Generator Sets

Equipment Introduction

The 300 series syngas generator sets is driven by combustible gas generated from biomass gasifiers with agricultural and

forestry wastes like rice husk,straw, wood chips as raw materials. The way to take the place of expensive petroleum

resources in short supply with rice husks, straws, wood powders,saw dust, etc. is with the features of better

comprehensive economic benefit and less environmental pollution caused by the direct combustion of rice husks and

straws.It’s of great significance to establish an energy system with sustainable development, promote the social

economic development,and improve ecological environment.The power of 300 series syngas generator sets ranges from

400KW to 1000KW.

Equipment Introduction

The 300 series syngas generator sets is driven by combustible gas generated from biomass gasifiers with agricultural and

forestry wastes like rice husk,straw, wood chips as raw materials. The way to take the place of expensive petroleum

resources in short supply with rice husks, straws, wood powders,saw dust, etc. is with the features of better

comprehensive economic benefit and less environmental pollution caused by the direct combustion of rice husks and

straws.It’s of great significance to establish an energy system with sustainable development, promote the social

economic development,and improve ecological environment.The power of 300 series syngas generator sets ranges from

400KW to 1000KW.

Outline Dimensional Diagram of 8300 Biomass Gas Generator Sets

(only for reference; take the engineering diagram as criterion)

Outline Dimensional Diagram of 16V300 Biomass Gas Generator Sets

(only for reference; take the engineering diagram as criterion)

Technical Features

· The gas mixing device adopts a venturi mixer or an electronically controlled mixer to match the proper valve timing and

ignition advance angle to achieve normal combustion of the gas.

· The double-tube air intake system reduces the condensation of tar in the intake pipe, and has good maintainability and

high safety.

· The quasi-internal mixing air intake system and the air ratio control system realize the mixed combustion of the

combustible gas and the air in the combustion chamber, completely avoiding the problem of high hydrogen gas tempering

and shooting.

· Removable intake valve box can maintain intake valve and clean tar without removing cylinder head.

· Imported ignition system from HEINZMANN made in Germany to obtain high ignition energy and precise ignition time and

ensure the safety and reliability of ignition, so that the ignition requirements of biomass energy can be met.

Applicable Air Source Conditions of Generator sets

Syngas should be properly defocused, filtered, gas-liquid separated, and stabilized before use. If the gas is at a high

temperature, it should be treated in a cooling system, and the gas temperature should not exceed 40 °C before

entering the machine. Air source conditions: pressure 2.5-10kpa, pressure change rate ≤1kPa/min, tar content

≤50mg/Nm3, ≤50mg/Nm3, ≤20mg/Nm3, moisture content≤40mg/Nm3, impurity particle size≤5μm, impurity

content≤30mg/Nm3, required gas calorific value≥4MJ/Nm3.

· The gas mixing device adopts a venturi mixer or an electronically controlled mixer to match the proper valve timing and

ignition advance angle to achieve normal combustion of the gas.

· The double-tube air intake system reduces the condensation of tar in the intake pipe, and has good maintainability and

high safety.

· The quasi-internal mixing air intake system and the air ratio control system realize the mixed combustion of the

combustible gas and the air in the combustion chamber, completely avoiding the problem of high hydrogen gas tempering

and shooting.

· Removable intake valve box can maintain intake valve and clean tar without removing cylinder head.

· Imported ignition system from HEINZMANN made in Germany to obtain high ignition energy and precise ignition time and

ensure the safety and reliability of ignition, so that the ignition requirements of biomass energy can be met.

Applicable Air Source Conditions of Generator sets

Syngas should be properly defocused, filtered, gas-liquid separated, and stabilized before use. If the gas is at a high

temperature, it should be treated in a cooling system, and the gas temperature should not exceed 40 °C before

entering the machine. Air source conditions: pressure 2.5-10kpa, pressure change rate ≤1kPa/min, tar content

≤50mg/Nm3, ≤50mg/Nm3, ≤20mg/Nm3, moisture content≤40mg/Nm3, impurity particle size≤5μm, impurity

content≤30mg/Nm3, required gas calorific value≥4MJ/Nm3.

Main Technical Specification Of The Biomass Gas/Producer Gas Generating Set(50HZ/60HZ)

| Project | Technical specification | ||||||||

|

Generator sets |

Model of the set | 400 GFLS | 500 GFLS | 800 GFLS | 1000 GFLS | ||||

| Rated Power(KW) | 400 | 500 | 800 | 1000 | |||||

| Rated Voltage(KV) | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | |

| Rated Current(A) | 721 | 656 | 902 | 820 | 1443 | 1312 | 1804 | 1640 | |

| Rated Frequency(HZ) | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | |

| COS Φ Power Factor | Lagging | ||||||||

| Mode of Excitation | Brushless | ||||||||

| Phase & Connection | 3 Phases 4 Wires | ||||||||

| Generator Model | 1FC6 SIEMENS | ||||||||

| Overall Dimensions(mm) | 6500*1830*3100 | 8287*2421*2782 | |||||||

| Net Weight(kg) | 22000 | 40000 | |||||||

| Engine | Model of Engine | TNJD-8300Q1 | TNJD-8300Q2 | TNJD-16V300Q1 | TNJD-16V300Q2 | ||||

| Mode | Water-cooling,Four-stroke,Spark plug ignition,Open combustion chamber | ||||||||

| Natural aspirated | |||||||||

| Arrangement of Cylinder | In-line 8-cylinder | V model 16 cylinders | |||||||

| Cyclinder Diameter(mm) | 300 | ||||||||

| Stroke(mm) | 380 | ||||||||

| Rated Power(KW) | 440 | 550 | 880 | 1100 | |||||

| Speeding(r/min) | 500 | 600 | 500 | 600 | |||||

|

Direction of Rotation (Dependent on Flywheel Start-up Mode) |

Counterclockwise | ||||||||

|

start-up Mode |

Compressed Air | ||||||||

|

Exhaust Temperature of Cylinder(℃) |

≤580 | ||||||||

|

Temperature of Gas Tunrel Boring Machines(℃) |

≤40 | ||||||||

|

Gas Pressure(Kpa) |

≥2.5 | ||||||||

|

Oil Consumption(g/kwh) |

≥1.0 | ||||||||

160、190 Series Technical Specification of 100-500KW Biomass Gasification Power Generation

| 3 phrases 4 wires, 50HZ/1000 r/min , Power Factor0.8 | ||||

| Model of Gas Gensets | Rated Power(KW/kvA) | Model of Gas Engine | Boundary Dimension(mm) | Net Weight(Kg) |

| 100GFLS | 100/125 | TNJD-6160Q1 | 1850×800×1430 | 4300 |

| 300GFLS | 300/375 | TNJD-12V190 | 5120×2040×2195 | 12000 |

| 400GFLS | 400/500 | TNJD-12V190T | 5120×2040×2780 | 12000 |

| 500GFLS | 500/625 | TNJD-12V190T | 5120×2040×2780 | 12000 |

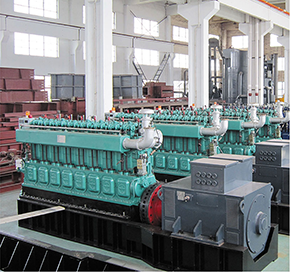

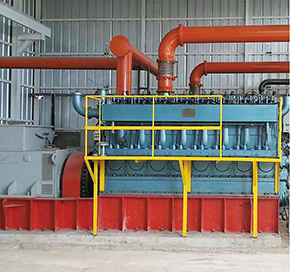

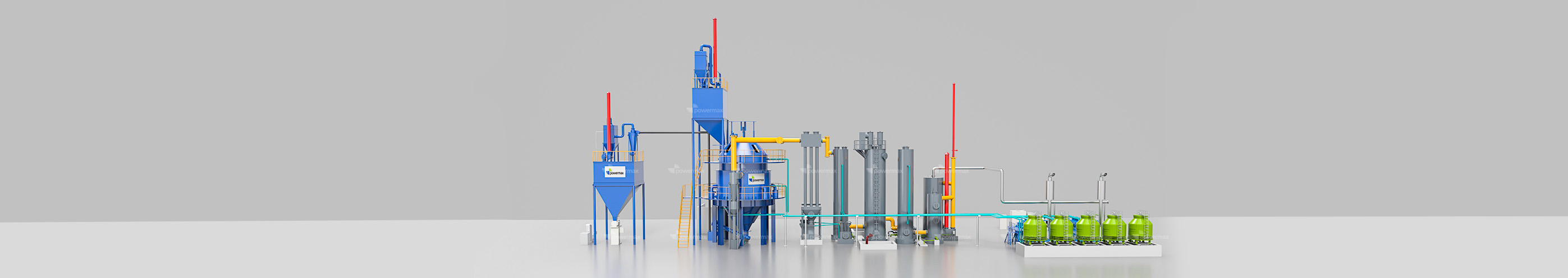

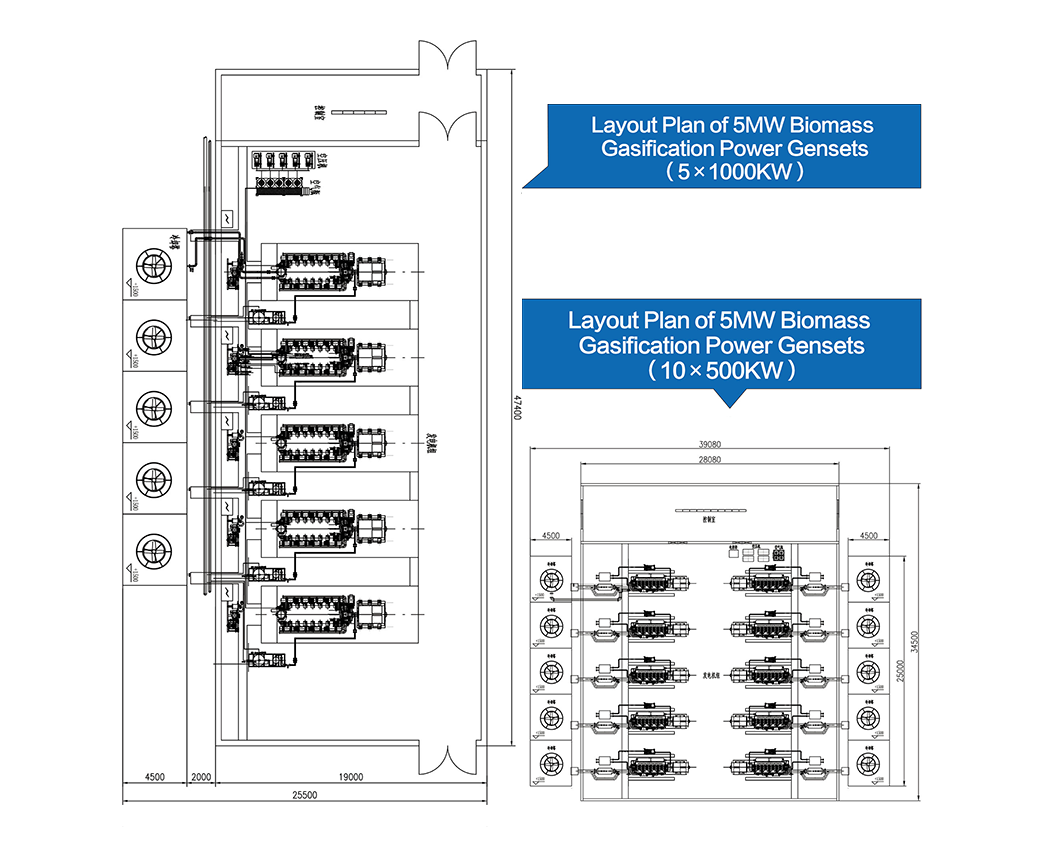

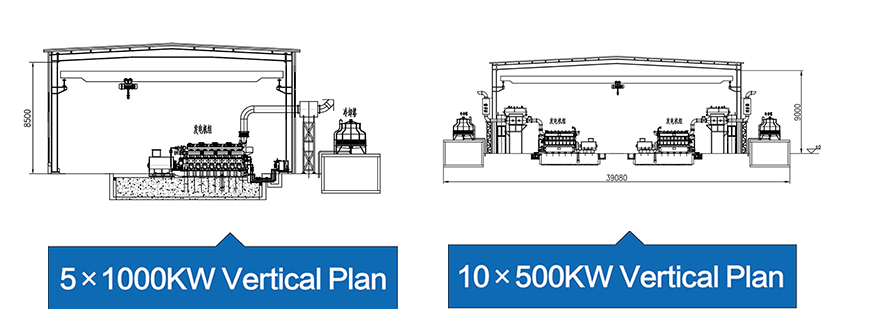

Arrangement of powermax 300 series

biomass gasification power gensets

biomass gasification power gensets

Powermax Project Presentation

Feedback form contact with us