|

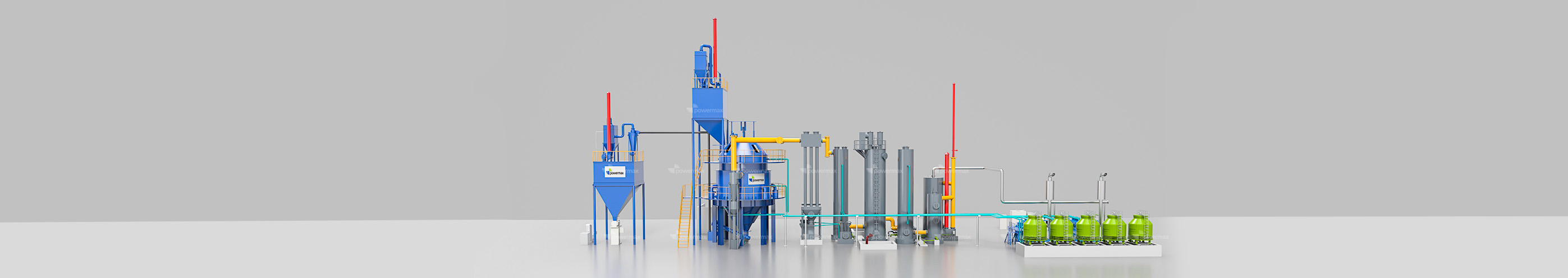

Applications for CLEANMAX Flue Gas Cleaning System |

|

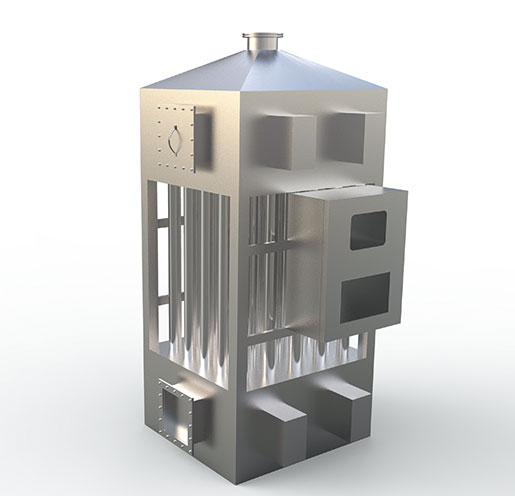

Municipal Waste(MSW) Incineration,Pyrolysis,gasification |

|

BiomassIncineration,torrefaction,carbonization,pyrolysis,gasification |

|

Hazardous waste Incineration,carbonization,pyrolysis,gasification |

|

Industrial Waste Incineration,pyrolysis,gasification |

|

Sludge Incineration,carbonization,pyrolysis,gasification |

|

Coal Fire Plant,coal Pyrolysis&gasification plant,coke-oven plant |

|

Exhaust Gas from Heavy Fuel Oil Engines in Diesel Power Plant |

|

Printing and dyeing mill,bitumen plant.dryer plant,kiln plant and etc. |

|

|

|

Main Features of CLEANMAX Flue Gas Cleaning System |

|

High Filtration efficiency |

|

Low operation costs,Low pressure losses, Low maintenance costs |

|

High available,Proven system used in actual practice |

|

Performance tange,Approx.100-800,000Am3/h |

|

Model |

Processing

Capacity(m3/h)

|

Qty of Cellular |

Sectional Area of

electric Field (m2)

|

Diameter(m) |

Length(m) |

Operating

Temperature(℃)

|

Operating

Pressure(Kpa)

|

Operating

Efficient(%)

|

Support

Power(A/KV)

|

|

TNJD19-II |

3000-3800 |

19 |

1.02 |

1.60 |

10.8 |

20-80 |

<50 |

≥98 |

0.1/72 |

|

TNJD24-II |

3800-4600 |

24 |

1.29 |

1.70 |

10.8 |

20-80 |

<50 |

≥98 |

0.1/72 |

|

TNJD31-II |

4600-5800 |

31 |

1.67 |

2.00 |

10.8 |

20-80 |

<50 |

≥98 |

0.1/72 |

|

TNJD37-II |

5800-7200 |

37 |

1.99 |

2.10 |

10.8 |

20-80 |

<50 |

≥98 |

0.1/72 |

|

TNJD44-II |

7500-9400 |

44 |

2.37 |

2.20 |

10.8 |

20-80 |

<50 |

≥98 |

0.15/72 |

|

TNJD64-II |

9500-12000 |

64 |

3.45 |

2.70 |

10.8 |

20-80 |

<50 |

≥98 |

0.2/72 |

|

TNJD74-II |

12000-15000 |

74 |

3.99 |

2.85 |

11.8 |

20-80 |

<50 |

≥98 |

0.2/72 |

|

TNJD90-II |

15000-19000 |

90 |

4.85 |

3.10 |

12.8 |

20-80 |

<50 |

≥98 |

0.3/72 |

|

TNJD104-II |

18000-22000 |

104 |

5.60 |

3.25 |

12.8 |

20-80 |

<50 |

≥98 |

0.4/72 |

|

TNJD114-II |

22000-26500 |

114 |

6.14 |

3.38 |

13.0 |

20-80 |

<50 |

≥98 |

0.4/72 |

|

TNJD130-II |

25000-30000 |

130 |

7.00 |

3.60 |

13.0 |

20-80 |

<50 |

≥98 |

0.5/72 |

|

TNJD150-II |

28000-34000 |

150 |

8.08 |

3.90 |

13.2 |

20-80 |

<50 |

≥98 |

0.6/72 |

|

TNJD170-II |

32000-38000 |

170 |

9.16 |

4.05 |

13.4 |

20-80 |

<50 |

≥98 |

0.6/72 |

|

TNJD196-II |

38000-46000 |

196 |

10.55 |

4.50 |

13.6 |

20-80 |

<50 |

≥98 |

0.8/72 |

|

TNJD220-II |

43000-52000 |

220 |

11.85 |

4.80 |

13.8 |

20-80 |

<50 |

≥98 |

1.0/72 |

|

TNJD248-II |

48000-58000 |

248 |

13.36 |

5.00 |

14.0 |

20-80 |

<50 |

≥98 |

1.2/72 |

|

TNJD276-II |

54000-65000 |

276 |

14.87 |

5.30 |

14.0 |

20-80 |

<50 |

≥98 |

1.2/72 |

|

TNJD300-II |

60000-70000 |

300 |

16.16 |

5.40 |

14.1 |

20-80 |

<50 |

≥98 |

1.5/72 |

|

TNJD346-II |

60000-80000 |

346 |

18.64 |

5.80 |

14.6 |

20-80 |

<50 |

≥98 |

1.5/72 |

|

TNJD388-II |

80000-90000 |

388 |

20.90 |

6.00 |

15.0 |

20-80 |

<50 |

≥98 |

1.5/72 |

|

TNJD400-II |

85000-95000 |

400 |

21.55 |

6.20 |

15.0 |

20-80 |

<50 |

≥98 |

1.8/72 |

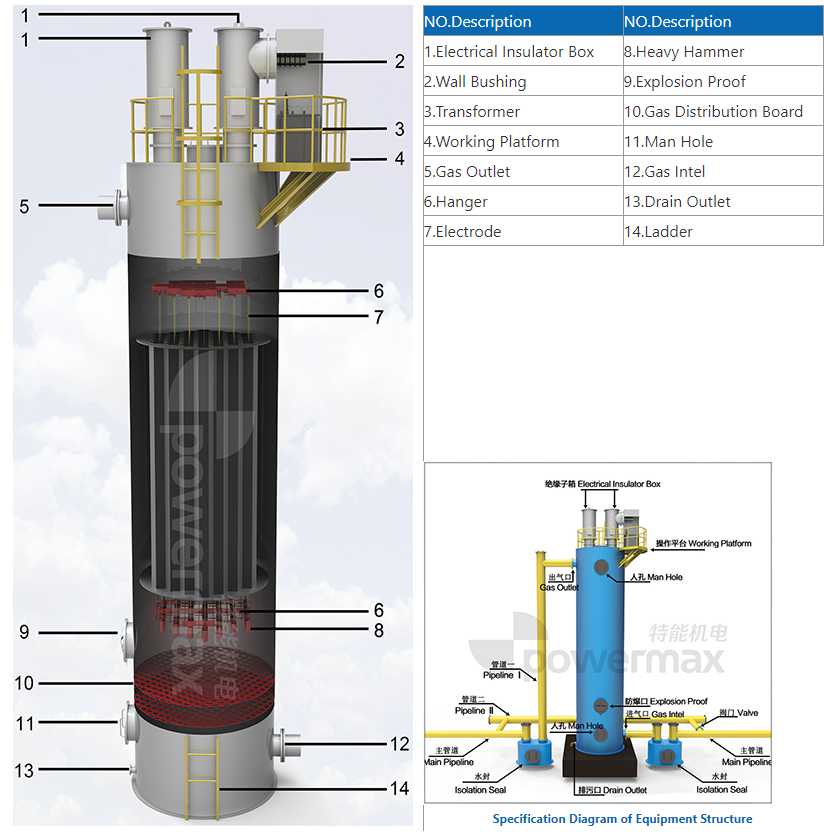

Technical parameters of TNJD-I High Voltage Electrostatic Tar Precipitator

|

Model |

Processing |

Qty of Cellula |

Sectional Area of |

Diameter(m) |

Length(m) |

Operating |

Operating |

Operating |

Support |

|

TNJD31-I |

6000-7500 |

31 |

2.41 |

2.30 |

10.8 |

20-80 |

<50 |

≥98 |

0.1-0.2/72 |

|

TNJD44-I |

8000-10000 |

44 |

3.42 |

2.80 |

10.8 |

20-80 |

<50 |

≥98 |

0.1-0.2/72 |

|

TNJD52-I |

10000-12000 |

52 |

1.04 |

3.00 |

10.8 |

20-80 |

<50 |

≥98 |

0.1-0.4/72 |

|

TNJD64-I |

12000-16000 |

64 |

4.98 |

3.20 |

10.8 |

20-80 |

<50 |

≥98 |

0.2-0.4/72 |

|

TNJD76-I |

14000-18000 |

76 |

5.91 |

3.40 |

11.8 |

20-80 |

<50 |

≥98 |

0.2-0.4/72 |

|

TNJD90-I |

16000-18500 |

90 |

7.00 |

3.70 |

12.8 |

20-80 |

<50 |

≥98 |

0.2-0.4/72 |

|

TNJD102-I |

18000-21000 |

102 |

7.93 |

3.90 |

12.8 |

20-80 |

<50 |

≥98 |

0.2-0.4/72 |

|

TNJD114-I |

20000-24000 |

114 |

8.86 |

4.30 |

13.0 |

20-80 |

<50 |

≥98 |

0.4-0.6/72 |

|

TNJD126-I |

26000-32000 |

126 |

9.80 |

4.35 |

13.0 |

20-80 |

<50 |

≥98 |

0.4-0.6/72 |

|

TNJD144-I |

36000-40000 |

144 |

11.20 |

4.60 |

13.2 |

20-80 |

<50 |

≥98 |

0.4-0.6/72 |

|

TNJD160-I |

40000-44000 |

160 |

12.44 |

5.00 |

13.4 |

20-80 |

<50 |

≥98 |

0.6-0.8/72 |

|

TNJD196-I |

40000-48000 |

196 |

15.24 |

5.20 |

13.6 |

20-80 |

<50 |

≥98 |

0.6-0.8/72 |

|

TNJD220-I |

55000-65000 |

220 |

17.11 |

5.40 |

13.8 |

20-80 |

<50 |

≥98 |

1.0-1.2/72 |

|

TNJD90-I/2 |

32000-37000 |

90*2 |

7.00*2 |

3.70*2 |

12.8 |

20-80 |

<50 |

≥98 |

0.2-0.4/72*2set |

|

TNJD102-I/2 |

36000-42000 |

102*2 |

7.93*2 |

3.90*2 |

12.8 |

20-80 |

<50 |

≥98 |

0.2-0.4/72*2set |

|

TNJD114-I/2 |

40000-18000 |

114*2 |

8.86*2 |

4.30*2 |

13.0 |

20-80 |

<50 |

≥98 |

0.4-0.6/72*2set |

|

TNJD126-I/2 |

52000-64000 |

126*2 |

9.80*2 |

4.35*2 |

13.0 |

20-80 |

<50 |

≥98 |

0.4-0.6/72*2set |

|

TNJD144-I/2 |

72000-80000 |

144*2 |

11.20*2 |

4.60*2 |

13.2 |

20-80 |

<50 |

≥98 |

0.4-0.6/72*2set |

|

TNJD160-I/2 |

80000-88000 |

160*2 |

12.44*2 |

5.00*2 |

13.4 |

20-80 |

<50 |

≥98 |

0.6-0.8/72*2set |

|

TNJD196-I/2 |

80000-96000 |

196*2 |

15.24*2 |

5.20*2 |

13.6 |

20-80 |

<50 |

≥98 |

0.6-0.8/72*2set |

|

TNJD220-I/2 |

110000-130000 |

220*2 |

17.11*2 |

5.40*2 |

13.8 |

20-80 |

<50 |

≥98 |

1.0-1.2//72*2set |

-

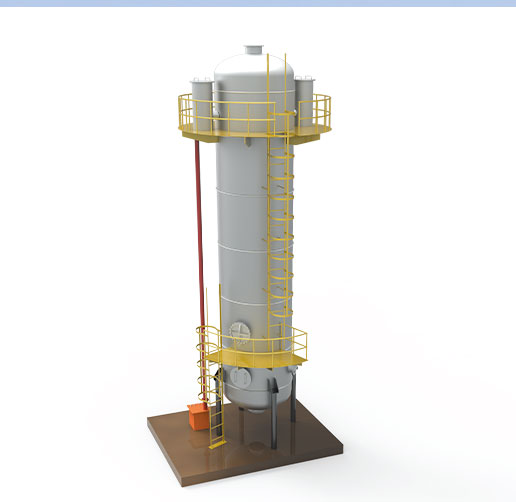

Coal Gasification ESP

-

Pitch Fume ESP

-

Sludge Pyrolysis and Gasification ESP

-

Biomass Gasification ESP

-

Waste Pyrolysis and Gasification ESP

-

Biomass Driect-fired ESP