- 1. Skip Charger

- 2. Biomass Surge Bunker

- 3. Air Blower

- 4. Gasifier

- 5. Cyclone Dust Collector

- 6.Tube Type Dust Remover

- 7. Venturi

- 8. Cyclone Hydraulic Separators

- 9. Electrical Tar Precipitator

- 10. Indirect Cooler

- 11. Water Drop Catcher

- 12. Booster Fan

- 13. Buffer Tank

- 14. Isolation Seal

- 15. Gas Flare

- 16. Gensets

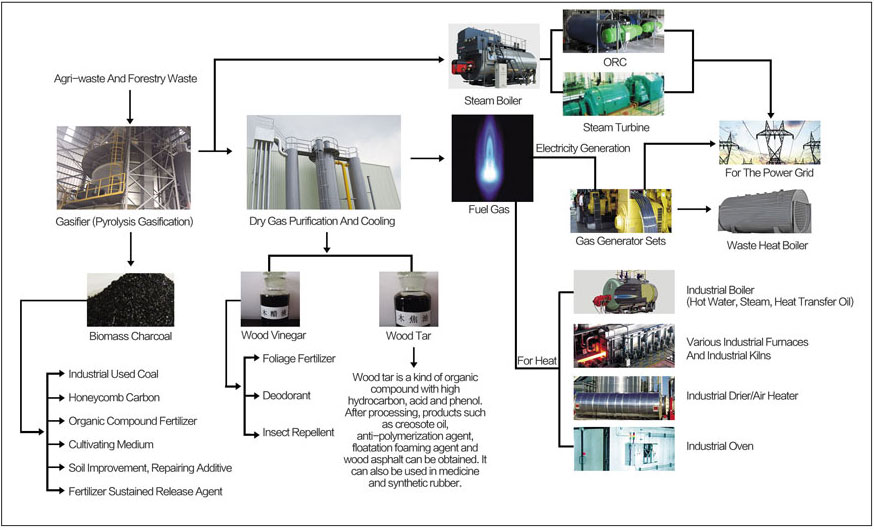

| Biomass Charcoal | Wood Tar | Wood Vinegar |

| Charcoal can be widely applied in our daily life, like cooking, baking, and rinsing in catering industry. In agriculture, it can improve the soil quality, promote the formation of soil aggregates, and regulate the soil ecosystem. Moreover, it can reduce the extractable metal content of the soil to promote the growth of crops. In industry, charcoal, coconut coal, palm shell charcoal are necessary raw materials in the production of activated carbon, and rice husk charcoal can be widely applied in smelting industry. | Wood tar is a kind of organic compound with high hydrocarbon, acid and phenol. After processing, products such as creosote oil, anti-polymerization agent, floatation foaming agent and wood asphalt can be obtained. It can also be used in medicine and synthetic rubber. | It is environmental friendly, and it can be applied to medicine original department (skin disease), food additive (fumigant), fuel original liquid (coal stain agent raw material), deodorant, pesticide raw material, etc. |

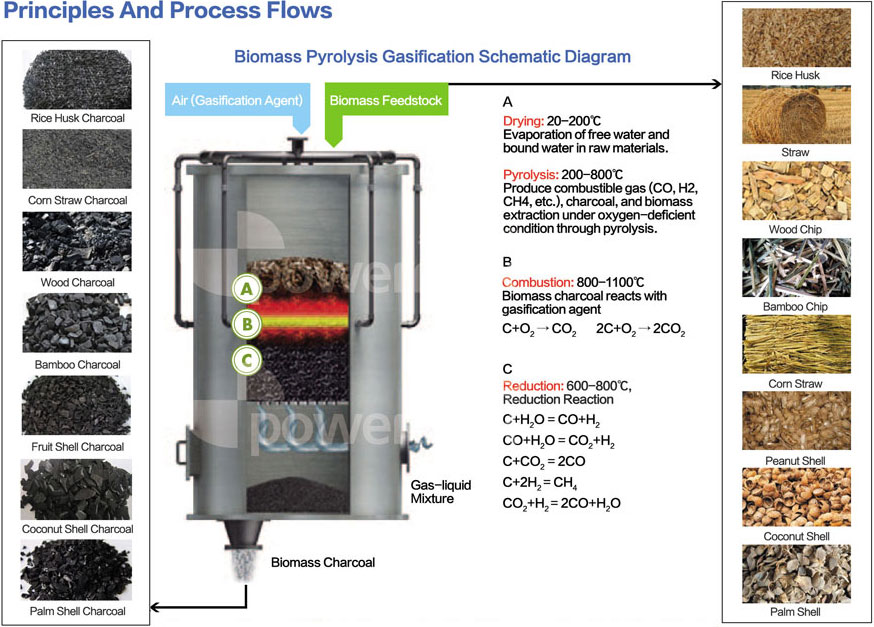

This technology uses thermochemistry conversion method. With Powermax independent R&D technology, biomass (rice husk, straw, cotton stalk, corn straw, wood ships, bamboo and other agriculture and forestry waste) can be converted into various kinds of products like syn-gas, electric energy, biomass charcoal, heat energy (steam, hot water), carbon basal fertilizer, foliage fertilizer. Moreover, the biomass can be turned into wealth and can be made full use of.

The basic principle of Powermax biomass gasification power generation system (BGPS) is to convert the agriculture and forestry products and wood processing remains such as rice husk, sawdust, branches, forestry waste, straw, rice straw, wheat straw, rice husk, shell, corn stalk, millet rod, cotton stem, bagasse, coconut shell, corn cob, corn cob wastes into gas, and use the combustible gas to drive gas generating equipment for electricity. It can not only solve the problems that biomass is difficult for combustion and collection, but also take full advantage of the equipment’s compact-design and environmental-friendly features. Therefore, it is one of the most eco-friendly way for biomass.

The process of Powermax biomass gasification power generation includes three steps. The first step is biomass gasification. Solid biomass is converted into combustible gas. The remaining product after fixed biomass gasification is biochar, which can be made into high-value carbon ink, barbecue charcoal, active carbon, etc. The second step is gas purification. The gas has impurities through gasification, including ash, charcoal, tar, which should be removed with purification system in order to ensure the operation of gas power generator. The byproduct after gas purification is biomass vinegar, which can be made into foliar fertilizer, deodorant, insecticide, etc. after concentration. The third step is gas power generation, which use gas engines (spark plug ignition type) for electricity generation, and the high temperature flue gas produced by the gas engine can heat boiler to get steam or hot water for residential or industrial use.

The Powermax biomass gasification power generation system adopts modular design, which can be normally applied to power stations of 50-20000kw. There are four models of Powermax biomass gasification power generation systems : circulating fluidized bed gasification system (CFGB), updraft fixed bed gasification system (UFBG), downdraft fixed bed gasification system (DFBG) and twin-fire fixed bed gasification system (TFBG). Each single set ranges from 50kw-3000kw. Powermax biomass gasification power generator sets use 500-1000rpm medium gas engine and efficient Siemens generators, and their specifications vary from 50kw to 1200kw. Powermax system is suitable for every kind of biomass.

Powermax Biomass Gasification Power Generation Technology Is Different From Other Renewable Energy Power Generation, Which Has Seven Characteristics As Following:

1)It is a short period for systematic supply and power plant construction. It takes 4-6 months from contract signing to power plant operation.

2)The total investment of power plant is low.

3)The system is typical of flexibility and simplicity. It can open and close at any time because Powermax Biomass gasification power generation system is composed of biomass gasifier and gas internal combustion engine(spark plug ignition), which needs low requirement for operators and low cost for operation and maintenance.

4)The system has better cleanliness. The emission of harmful gas such as CO2、SO2 can be decreased validly because the biomass belongs to renewable energy. What’s more, the temperature of gasification process is lower(about at 700-900℃) and the accumulation of NOX is few so that the emission of NOX can be controlled efficiently.

5)The system has higher economical efficiency. The flexibility of biomass gasification power generation system can ensure a higher economical efficiency of technology in small scale. At the same time, the simple process of gas power generation and compact equipment ensure that the investment of biomass gasification power generation technology is lower than other renewable energy power generation technology. In conclusion, biomass gasification power generation technology is cost-optimal power among all renewable energy technology.

6)Contrast with solar power generation, wind power generation and hydraulic power generation, the power generation time of biomass power generation system can reach 7200-8000h per year, which can get a faster return on investment.

7)The high utilization efficiency and economic benefit of bio-production: the gaseous production(flammable gas) is used for power generation, air supply and instead of coal. The hot water produced in gasification process can be used for bath and other uses, and the liquid product(wheat straw vinegar) can be made into leaf fertilizer, deodorant and so on. The solidoid (biochar) can be made into carbon basal fertilizer, active carbon, barbecue charcoal and so on.

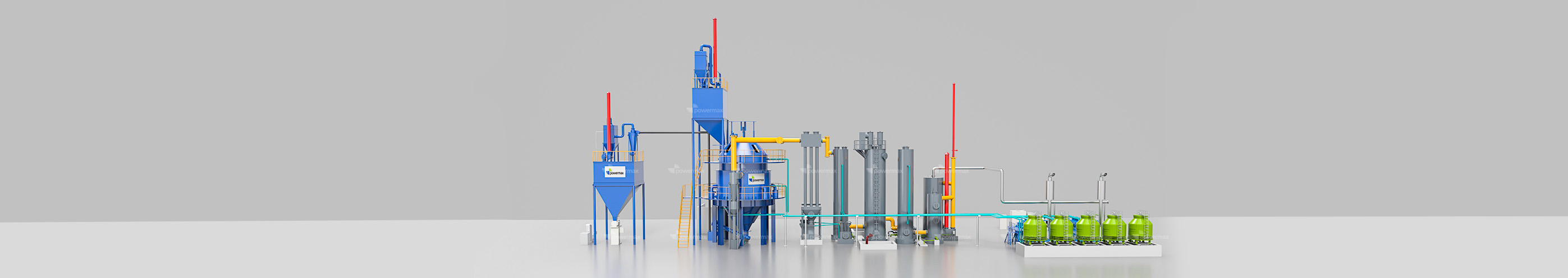

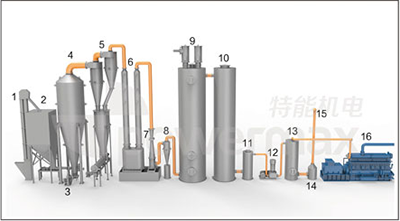

Bed Gasification Power Generation System

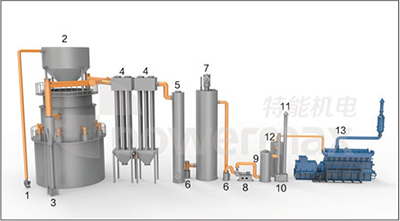

Bed Carbonization Power Generation System

- 1. Skip Charger

- 2. Biomass Surge Bunker

- 3. Air Blower

- 4. Gasifier

- 5. Cyclone Dust Collector

- 6.Tube Type Dust Remover

- 7. Venturi

- 8. Cyclone Hydraulic Separators

- 9. Electrical Tar Precipitator

- 10. Indirect Cooler

- 11. Water Drop Catcher

- 12. Booster Fan

- 13. Buffer Tank

- 14. Isolation Seal

- 15. Gas Flare

- 16. Gensets

The biomass pyrolysis gasification poly generation technology can efficiently transforms the biomass into electric energy or thermal energy and simultaneously produce the biomass carbon and the biomass wood vinegar. The electricity generated can be directly connected to the grid with a price subsidy of 0.75 CNY/KWH. Biochar not only can be used in insulation materials for steel plants, but also can be used as activated carbon, barbecue charcoal, and carbon fertilizer. The biomass extraction obtained by purification of wood vinegar is widely used in pharmaceutical and food industries or as leaf fertilizer.

Take 5MW Biomass Rice Husk Pyrolysis Gasification Co-generation of Electricity,Carbon, Liquid and Thermal System as an Example for Benefit Analysis

|

Project Name |

Unit |

Value |

Comment |

|

Consumption&Output |

|||

|

Biomass Consumption |

kg/h |

9,000 |

|

|

Generated Energy |

kw |

5,000 |

The long running load is 90% |

|

Biochar Yield |

kg/h |

2700 |

|

|

Biomass Extract Yield |

kg/h |

900 |

|

|

Steam Output |

t/h |

5 |

Waste heat utilization of generator sets |

|

Benefit Analysis |

|||

|

Total Project Investment |

USD |

10,242,003.72 |

Differences due to different price of distinct area |

|

Annual Running-time |

h |

7,500 |

|

|

Self-consuming Electricity |

% |

10 |

|

|

Fuel Cost |

USD |

3,950,487.15 |

58.53 USD/t |

|

Staff Salary |

USD |

526,731.62 |

|

|

Maintenance and Repair Costs |

USD |

117,051.47 |

|

|

Oil Consumption |

USD |

93,641.18 |

1kwh consuming 1g engine oil |

|

Equipment Amortization |

USD |

365,785.85 |

|

|

Management Cost |

USD |

43,894.30 |

|

|

Annual Total Cost |

USD |

5,097,591.57 |

|

|

Annual Line Capacity |

kwh |

33,750,000 |

Self-consumption electricity |

|

Annual Electricity Income |

USD |

3,703,215.92 |

0.11 USD/kwh |

|

Annual Biochar Income |

USD |

2,962,865.36 |

Charcoal 146.31 USD/t |

|

Annual Biomass Extract Income |

USD |

395,048.72 |

58.53 USD/t |

|

Annual Steam Income |

USD |

1,097,357.54 |

29.26 USD/t |

|

Annual Hot Water Income |

USD |

1,097,357.54 |

|

|

Gross Annual Income |

USD |

8,158,487.54 |

|

|

Annual Profit |

USD |

3,060,895.97 |

|

|

Investment Payoff Period |

year |

3.8 |

Half a year construction period included |

-

Biochar

-

Carbon Basal Fertilizer

-

Leaf Fertilizer

-

Insect Repellent

Mainly Three Kinds Of Biomass Coupling Power Generation Technologies At Present:

Biomass is mixed with coal and then put into boiler for combustion. This method has higher requirements for fuel treatment and combustion equipment, and has the problem of low temperature alkali metal corrosion. So the boiler burner needs to be remoulded.

The biomass burning boiler generates steam directly, and this part of steam can be fed into the reheater of pulverized coal furnace or into the low-pressure cylinder of steam turbine coupling method.This coupling mode, due to the existence of relatively independent biomass boiler system, has no influence on the combustion of coal-fired boilers. However, the system is complex, so the investment cost is little higher.

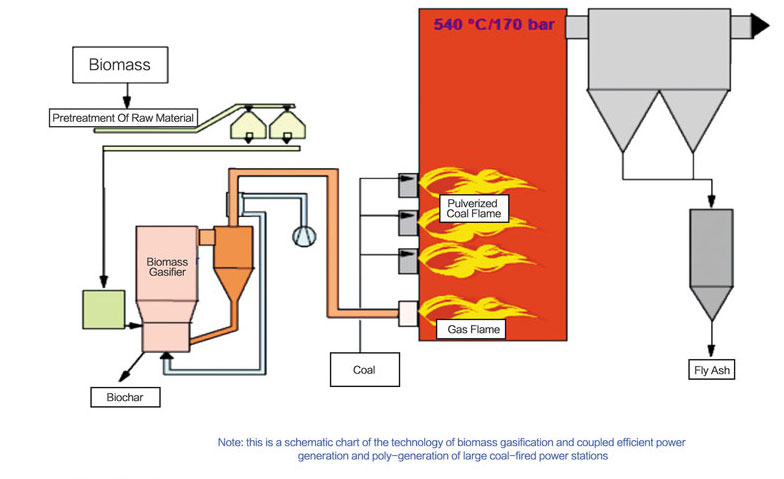

Biomass gasification produces gas, mixed with coal to combustion. This technology is the main application technology of biomass coupled power generation in China, which is called biomass gasification coupled efficient power generation and poly-generation technology.

The first two types of biomass coupling power generation technologies are types of biomass direct combustion, and the biomass gasification coupled efficient power generation and polygeneration technologies provided by Powermax are biomass gasification technologies.

Technical Principle

The gasification reaction of the biomass raw materials completed in the the gasification furnace, it is directly sent to the boiler of large coal-fired power station in the way of thermal gas after the gas generated is dedusted by the purification system, which is mixed with coal powder and utilized the original power generation system to achieve the purpose of efficient power generation. This technology makes use of the efficient parameters of large coal-fired power station units to convert biomass energy into electricity more efficiently, and the biochar generated from gasification can also gain considerable additional benefits, realizing the effective utilization of biomass, so as to alleviate the problems of energy crisis and greenhouse gas pollution.

Process Flow Chart

Environmental benefits: Due to biomass gas replacement of coal, it reduces CO2、SO2 emissions, while combustion of low calorific value gas in boilers reduces NOx emissions.

Economy:After the biomass gas is added into the boiler system, the efficient combustion of gas forms a high temperature zone, which is conducive to the complete combustion of coal powder. While the coal power system remains efficient, the efficiency of biomass conversion into electric energy can reach 37%, higher than the existing biomass direct combustion power generation (22-30%). The biochar obtained from gasification can be used as high quality energy, soil conditioner, reducing agent, fertilizer slow-release carrier and carbon dioxide sequestration agent, which have higher economic benefits.

Flexibility: This technical route is suitable for coal-fired power generating units of different capacities. Biomass gasification and reburning to generate power make full use of the original high-efficiency power generation equipment of the power station to ensure higher power generation efficiency in any scale.

National policy: Biomass gasification power generation can monitored by gas flow rate, temperature and gas composition parameters to calculate independently and electricity and power grid enterprises shall settle separately. At present the way has been officially confirmed by the national development and reform commission (Implementation of Biomass Power Generation Coal Coupling of the Pilot), and it can be offered with biomass electricity price subsidies

-

Hongze powermax biomass gasification power generation Co.,Ltd.

-

Hongze 5MW biomass gasification power generation system

-

Hanchuan 5MW biomass gasification power generation system